Winjeel is the name for “young eagle” used in Victoria by the original Australians, and the aircraft was designed and build in the Commonwealth Aircraft Corporation in that area during the 1950s. It was designed as a trainer aircraft to fly in the Royal Australian Air Force (RAAF), replacing the previous Wirraway and Tiger Moths, although it required some redesign to make it a little less stable so that spin-recovery training could be undertaken. In an effort to phase out the prop trainers, the powers that be tried to replace it with an imported Macchi jet trainer, which failed and led to an extension of the Winjeel’s service life until the mid-70s with a few serving until the 90s as a Forward Air Controller (FAC) after which time it was replaced by the Pilatus PC-9 turbo-prop.

The Kit

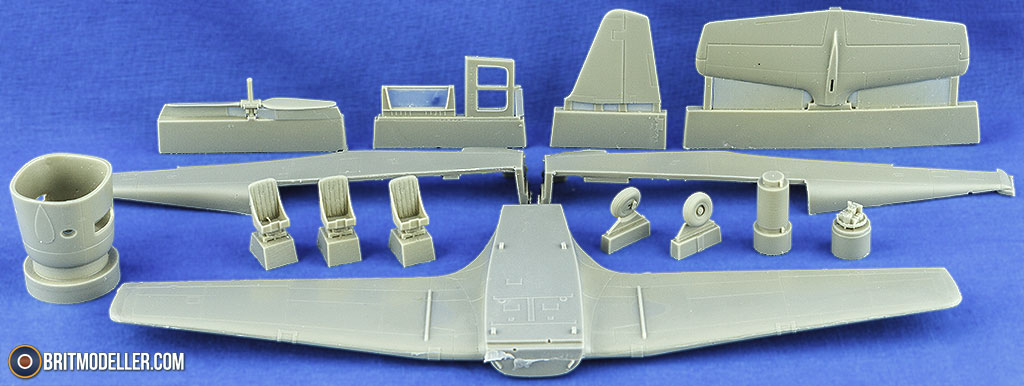

This is a Planet Models reboxing of the 2016 resin kit by Red Roo with amended decals, and should give some relief to those that have been in the market for one. It arrives in a smallish top-opening box with the parts inside heat-sealed partitioned bags to reduce the chances of chaffing or breakage of the small parts during shipping or moving around once you own it. A few of the exhaust collector pipes had broken off in my sample, but these were easily glued back with small quantities of super glue There are three main bags of parts, with the larger fuselage and heavier full-span wings kept separate from the smaller parts for obvious reasons. The two vacformed canopies are again in another bag with the Photo-Etch (PE), a pre-printed acetate sheet, clear resin parts and white metal parts, plus of course the decal sheet. The instruction booklet is A5 and has colour profiles on the rear pages for painting and markings.

Resin usually comes still attached to its pour block, which is where the liquid resin is poured into the mould and acts as an overflow and bubble-catcher for more rustic manufacturers that don’t have access to pressure casting methods. These will have to be removed before you can assemble or paint the parts, so there will be a little extra time needed to prepare the model for construction. With resin, you should take the precaution of wearing a mask when cutting or sanding it, as the tiny particles are harmful to your health if breathed in, which is the same with all small particles. Washing the parts in warm water will remove any sanding residue and also improve the adhesion of paint, as there may still be some mould release agent on the parts when you receive them. Take care not to use water that is too hot, as this may cause deformation to more delicate parts, and this technique can conversely be used to fix warped parts, followed by cold water to “freeze” the changes in the parts.

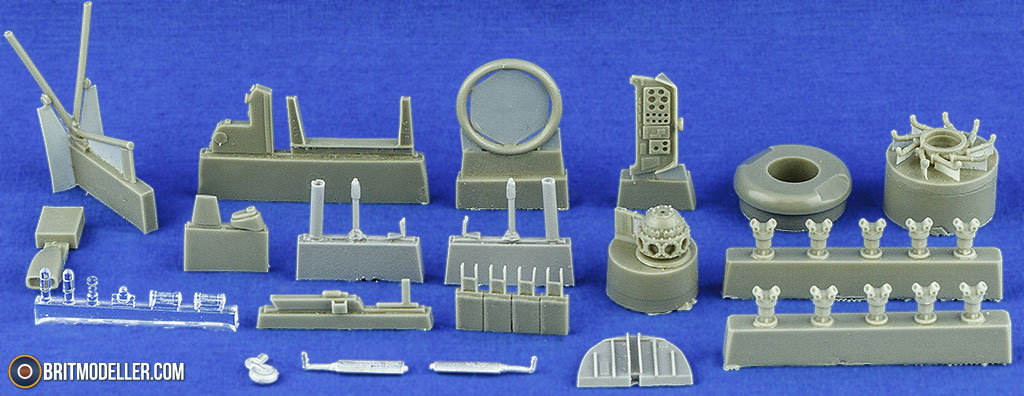

Construction begins with the wings for a change, cutting out segments of the leading edge on each side to accommodate the clear landing lights, which you can drill out the back of to depict the lights inside. A number of small parts are fitted to the cockpit floor, which is also the top surface of the wing, then the fuselage halves are also detailed with resin and PE parts before it is closed up and mated with the wing in close succession. The elevators are placed on the flat at the rear of the fuselage with the tail fit inserted into the slot on the top, then there is a brief pause while the complete Pratt & Whitney R-985-AN-2 Wasp Junior nine-cylinder radial engine is made up around a central hub with separate cylinders, wiring loom, exhaust collector and an aft spacer part so that it sits correctly within the cowling. There are three seats within the cockpit, and they all have four-point seatbelts supplied on the PE fret, backed by a rectangular panel toward the rear of the cockpit, the majority of which is painted a bright grass green in some airframes. The front of the fuselage has two circular parts installed, followed by the engine and finally the cowling, which is cast as a single part with flashed-over cooling ports that will help show off your work on the engine when complete.

The instrument panel is backed by a resin part, with a small lump on top that is only necessary for the FAC role, so should be removed if necessary for your choice of decal. There are two PE panels and acetate backers supplied, one for the trainer, the other for the FAC aircraft, so again choose your panel depending on your decal choice, or leave the resin panel and paint that if you prefer, and add the roll-over frame over the seats for those inevitable accidents. A tiny rudder actuator arm is fitted low-down on the fin and on all the trim-tabs, then four small clear resin lights are glued inside the cockpit, at the very tip of the tail and at each wingtip. Underneath the aircraft the white metal tail-wheel is installed in the rear, an intake and exhaust are glued under the nose with two PE parts joining them. The wheels are fixed, and the white metal struts are given PE scissor-links and brake lines, then glued to the underside of the wing into small depressions, adding wheels and pitot probe later.

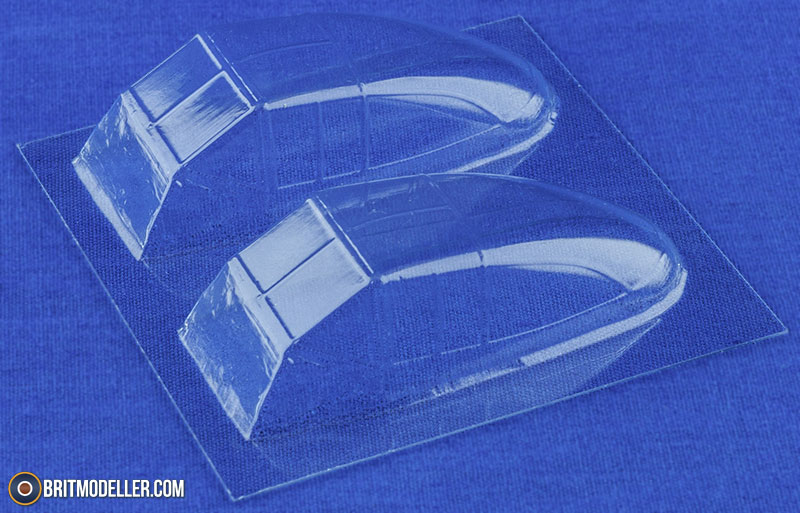

The canopy is vacform and beautifully clear as a result, doubled-up just in case you have an accident or want to cut it to open up the cockpit and make a slip-up. Careful cutting with some Blutak holding the canopy in shape, followed by careful sanding of the edges to ensure a good fit will see you with a spare to offer to others in the future if they have problems. The FAC version has a small aerial in front of the cockpit and blade antenna at the rear, plus a windscreen wiper and sensors in front of the windscreen, leaving just the two-blade prop to be slid into the bell-housing of the engine.

Markings

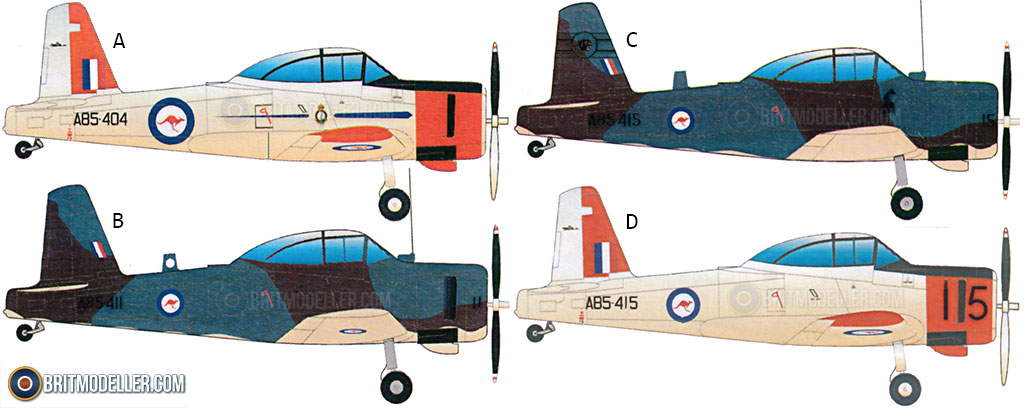

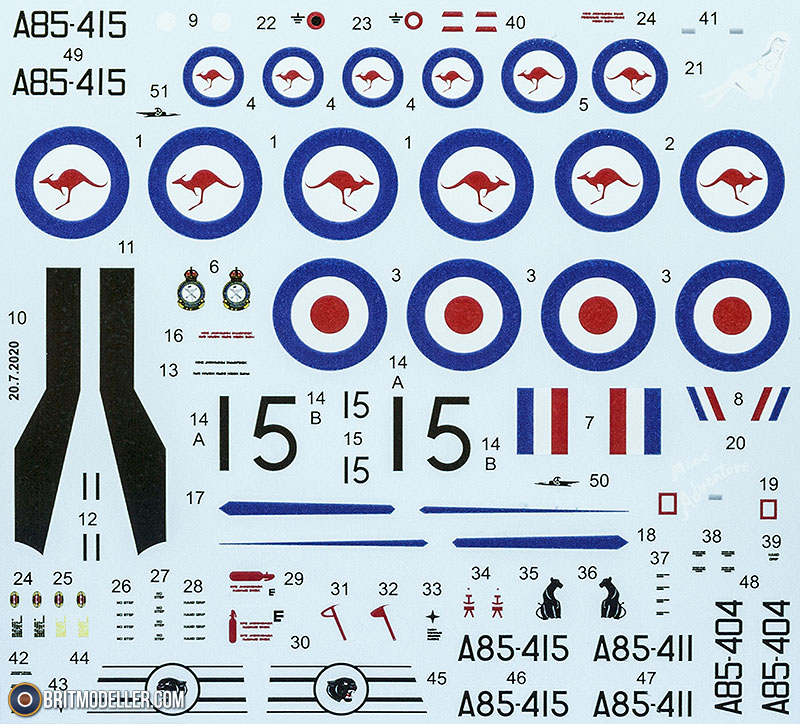

There are four markings options in the box, with four-view colour drawings of each option at the rear of the instruction booklet, allowing you to make one of the following:

- A85-404, No.1 Basic Flying Training School, RAAF Point Cook, 1964

- A85-411, FAC Aircraft, No.76 Sqn. RAAF Williamtown, 1990

- A85-415, FAC Aircraft, No.76 Sqn. RAAF Williamtown, 1990

- A85-415, No.1 Basic Flying Training School, RAAF Point Cook, 1965

The decals are anonymously printed, but generally have good register, sharpness and colour density, except for a little bleed on one of the blue arrows, but that can easily be cut off before application. The glossy carrier film has been printed slightly high too, but it still covers the printed areas so shouldn’t be of issue.

Conclusion

A welcome re-release of a niche product made and flown by our Australian allies after WWII. Detail is good, casting blocks sensibly placed, and with the addition of PE, white metal, clear resin and two vacform canopies, that detail is improved even further.

Highly recommended.

Loading... Please wait...

Loading... Please wait...